Subscribe to our newsletter for timely content in your inbox

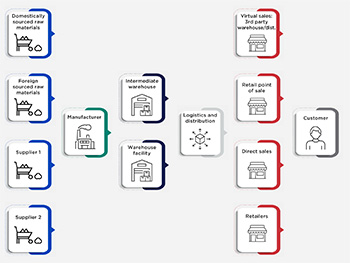

Mapping the supply chain is the first step in conducting a thorough supply chain assessment. This process helps identify vulnerabilities that could lead to business interruptions.

After mapping and assessing your supply chain, it’s important to develop a proactive strategy to mitigate risks you identified. The next steps you can take include:

By taking these steps, you can build a more resilient and efficient supply chain, helping to ensure business continuity and success.