Inspection and maintenance of non-regulated fleets

Organizations should have a formal vehicle inspection and maintenance program to ensure safe operation of owned and non-owned vehicles. A well-maintained fleet can maximize productivity, reduce accidents, and improve morale.

Productivity and costs - A well-maintained fleet will minimize operational costs. Unexpected breakdowns create a domino effect in added costs from emergency repairs, towing, expedition of replacement parts and replacement vehicle rentals. Productivity and customer service are impacted when vehicles are sidelined, and service or deliveries are delayed.

Safety – Vehicle component wear or failure can lead to loss of control and other accidents. Breakdowns, particularly along a roadway, place stranded employees in an unsafe environment.

Employee retention – In today’s work environment, employees expect clean, well-maintained vehicles. Breakdowns and unscheduled downtime create undue stress on drivers and mechanics. Keeping vehicles in good repair is key to employee retention.

Key program elements include:

- A designated individual responsible for overseeing the program.

- Inspection and maintenance (IM) frequency in accordance with vehicle manufacturer guidelines. More frequent IM when vehicles get older or are operated in harsh environments.

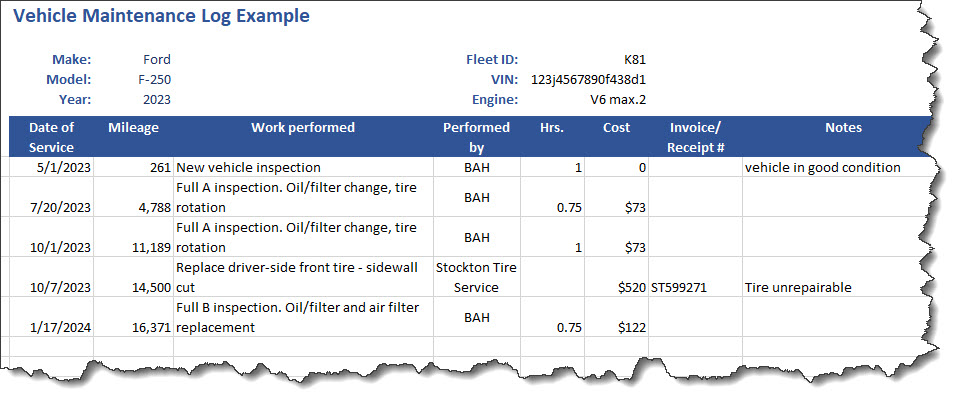

- A scheduling and tracking system to ensure critical IM is not missed. Vehicle maintenance software is available to assist this process. Smaller organizations can utilize a basic spreadsheet.

- Organizations will often stipulate different levels of inspection/service based on mileage. For example, an “A” level may be an oil change and tire rotation plus a basic inspection of fluid levels, belt conditions, tires, etc. Level “B” service/inspections would include more in-depth activities such as inspection of brakes, wheel alignment, testing of fluids, etc.

- Work completed by competent individuals. All work should be done under the supervision of a National Institute of Automotive Service Excellence (ASE) Master Certificate Mechanic.

- Proper vetting of outside services. Vendors should have ASE certified staff or be otherwise qualified. If not using a dealership or national chain, certificates of insurance should be obtained to ensure adequate insurance is in place for faulty workmanship. A Garage Liability policy with $2,000,000 per occurrence limits should be minimum.

- Retention of all records. All IM should be documented with repair records maintained in vehicle specific folders.

- A vehicle replacement schedule to ensure vehicles are not kept beyond a point where component failure and breakdowns become more frequent.

Driver and manager inspections

Adhering to manufacturer service guidelines is important but there are often long periods of time between service intervals where components can fail, such as a taillight burning out or a tire being cut on road debris. To ensure vehicles remain safe between designated service intervals, drivers and managers should conduct their own inspections.

- Drivers should perform a walk-around inspection of their vehicle before each trip. Walkarounds can identify obvious problems such as low tires, fluid leaks and vehicle damage; typically taking less than 30 seconds. Additionally, walkarounds can identify potential hazards such as child’s bike recently left nearby or another car that has parked too close.

- Drivers should be required to perform a detailed monthly vehicle inspection using a specific inspection form. Quarterly may be appropriate for newer vehicles not subject to harsh conditions or heavy miles.

- Managers should conduct documented inspections of their staff's vehicles 2-4 times a year to ensure drivers are not neglecting safety issues or required maintenance. A best practice is to conduct this inspection with the driver as a learning exercise and to discuss any problems the driver may be aware of that are not readily apparent.

Telematics aids in vehicle maintenance

Most vehicle telematics systems have vehicle maintenance features available at no cost or as an inexpensive option. These features include:

- Maintenance scheduling and tracking. Because telematics tracks vehicle mileage, it supports mileage-based scheduling, alerting a maintenance manager or driver that an inspection or maintenance is due. Most systems allow for recording when the task is completed, and many allow uploading of an inspection report or repair invoice. This works particularly well for organizations that rely on drivers to take their vehicle in for oil changes and other scheduled maintenance.

- Diagnostic Trouble Codes (DTC). Most telematics systems plug into a port connected to the engine control module. This allows many telematic systems to read DTC codes, which are fault codes that trigger dashboard warning lights. DTC alerts can notify the driver and maintenance personnel of the specific engine problem so they can be addressed before severe engine damage or breakdowns occur. DTC code alerts are particularly valuable to fleet managers with vehicles operating in remote areas.

Non-Owned Vehicles

Employees who use their own vehicles for company business expose your organization to similar crash liabilities as an owned vehicle. Therefore, an organization should have controls in place to ensure the employee’s vehicle is well maintained and in good repair. Appropriate controls include:

- Preapproval of the vehicle to be used, including a documented inspection by a qualified mechanic within the last 12 months.

- Annual inspections by a certified mechanic and periodic documented manager inspections of the vehicle.

- Requiring a daily driver walk-around and monthly driver documented inspection. Quarterly may be appropriate for newer vehicles not subject to harsh conditions or heavy miles.

- Requiring the owner to maintain their vehicle according to manufacturer requirements.

- Establishing a maximum vehicle age (7-10 years) and mileage (125K-150K) requirement.