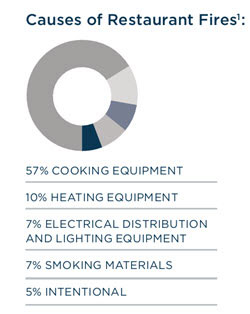

Commercial kitchen fire safety

Commercial cooking equipment is the leading cause of fires in U.S. eating and drinking establishments,1 but designing your kitchen the right way — and making sure equipment and fire suppression systems are properly maintained and inspected — can help protect your business against costly cooking fires. To that end, standards developed by the National Fire Protection Association (NFPA) and UL (Underwriters Laboratories) are suggested reading for all owners and operators of:

- Convenience stores

- Diners

- Fast-food restaurants

- Gourmet restaurants

- Hotel kitchens

- Retail food courts

- School cafeterias

- Service kitchens

NFPA 96: Your guide to commercial kitchen fire safety

“NFPA 96: Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations” sets minimum fire safety requirements (preventive and operative) related to the design, installation, operation, inspection and maintenance of commercial kitchens.

Essentially, NFPA 96 offers you a guide to help prevent fires originating on or in relation to grease-producing cooking surfaces. The standard establishes requirements for a variety of commercial cooking equipment, including hoods, ventilation and extinguishing systems, as detailed later in this article.

UL 300: Your guide to effective kitchen fire suppression

“UL 300: Standard for Fire Testing of Fire Extinguishing Systems for Protection of Commercial Cooking Equipment” was introduced in the 1990s because of two key changes in commercial kitchens: 1) the movement on the part of health-conscious chefs to begin cooking with vegetable fats, which have a higher auto-ignition point (685° Fahrenheit) than animal fats (550° F), and 2) the introduction of state-of-the-art cooking equipment that’s better insulated and slower to cool than older equipment.

“UL 300: Standard for Fire Testing of Fire Extinguishing Systems for Protection of Commercial Cooking Equipment” was introduced in the 1990s because of two key changes in commercial kitchens: 1) the movement on the part of health-conscious chefs to begin cooking with vegetable fats, which have a higher auto-ignition point (685° Fahrenheit) than animal fats (550° F), and 2) the introduction of state-of-the-art cooking equipment that’s better insulated and slower to cool than older equipment.

Unlike the wet chemical systems recommended by UL 300, the dry chemical suppression systems previously used in commercial kitchens are not effective in suppressing the hotter fires. As a result, UL issued the new standard, described in greater detail later in this article.

NFPA 96 and what it encompasses

NFPA 96 is the accepted fire safety standard for all commercial kitchens, listing requirements for the full spectrum of cooking equipment, hoods, exhaust duct systems, grease removal devices, fans and fire suppression systems.

NFPA 96-compliant systems:

- Safely capture, contain and exhaust grease-laden vapors, heat, moisture and smoke

- Automatically engage and extinguish grease fires

- Eliminate the need for a constant supply of suppressing agent

- Block any danger of a violent reaction that could spread flames or spill cooking oil

- Feature automatic fuel shut-offs for gas and electric

Hood

The key component for capturing smoke and grease-laden vapors is the kitchen hood. To be in compliance with NFPA 96, you need a hood that:

- Spans all cooking equipment

- Is constructed and supported by 18-gauge carbon steel or 20-gauge stainless steel, at a minimum, with liquid-tight seamless welds at all seams and joints

- Has no combustible materials located within a minimum of 18 inches

- Is not penetrated in any way, unless such penetrations are approved and have the same structural integrity as the hood

- Has no electrical equipment (wiring and motors) in the path of exhausting vapors; lighting units may be installed on the outer surface of the hood in steel enclosures with tight-fitting glass

Filters

Your kitchen’s grease filters, frames and mounting supports should:

- Be of noncombustible construction and UL-listed for commercial cooking equipment

- Be tight-fitting, designed for easy removal and installed at a 45-degree angle from horizontal

- Be equipped with an appropriately sized drip tray, not to exceed 1 gallon, installed at the lower edge of the filters

Grease extractors can be used, but only in accordance with the manufacturer’s suggestions, and they must be UL-listed. Also, there are UL-listed mesh filters, but those are less desirable because the limited amount of grease they can hold causes them to require more frequent cleaning.

DuctsIdeally, exhaust ducts direct vapors from the cooking operations to the exterior of the building in the most direct route possible. Ducts should not pass through firewalls or fire partitions, and they should not be interconnected with any other ventilation system in the building. In addition, ducts should:

- Be constructed and supported by 16-gauge carbon steel or 18-gauge stainless steel, at a minimum

- Have liquid-tight external welds, except where the duct joins the hood or grease removal device

- Provide an opening for cleaning at every point where a duct changes direction; such openings should be located on the side of the duct at least 1 inch to 2 inches above the bottom of the duct, and be equipped with steel opening covers the same strength and type as the duct itself so as to prevent the passage of grease or vapors under any condition

- Have no combustible materials located within a minimum of 18 inches

Ducts can be installed on both the interior and exterior of a building, but NFPA 96 specifications differ for indoor and outdoor installation.

Exhaust Equipment

To control grease-laden vapors, NFPA 96 specifies that an exhaust fan with a minimum speed of 500 feet per minute be provided for all commercial cooking equipment. The fan should:

- Always be operated with a filter

- Be equipped with a timer that allows the exhaust to run for two hours after the cooking equipment is shut off

- Continue to operate when automatic extinguishing equipment is activated

Electrical Equipment

All kitchen electrical equipment should be installed in accordance with “NFPA 70: National Electrical Code® .”2 This code requires that no wiring, motors, lights or other electrical devices be installed in ducts, hoods, concealed spaces or in the path of exhaust vapors. Many manufacturers include lights in steel enclosures of tight-fitting glass with their systems. As noted above, such lights should be installed on the outer surface of the hood.

UL 300 and what it encompasses

UL 300 is an industry standard that defines best practices for testing kitchen fire suppression systems. Since the 1990s, UL 300 has been the accepted standard for pre-engineered fire extinguishing systems intended for the protection of commercial cooking areas.

UL 300 extinguishing systems adequately protect exhaust hoods, plenums and ducts. Cooking appliances such as deep-fat fryers, griddles, range tops, woks, upright broilers and various types of charbroilers are also included within this standard. In addition to fire extinguishing tests, splash tests are conducted to ensure that the operation of the extinguishing system won’t splash burning grease.

Why the standard changed

The standard changed because animal fats autoignite at 550° F, while vegetable oils autoignite at 685° F, and modern cooking equipment stays hot longer. Dry chemical systems cannot suppress the higher heat, nor can they cool equipment quickly. Wet chemical systems can.

How UL 300 differs from previous standards

A UL 300-compliant fire protection system is more effective in controlling kitchen fires than earlier systems because:

- UL 300 systems use wet chemicals

- Wet chemicals smother hotter fires

- Wet chemicals are more effective than dry chemicals at preventing liquids from reigniting

What a UL 300-Compliant system includes

A UL 300-compliant systems include:

- Wet chemical suppression agent

- Nozzles located in the hood and duct

- Nozzles located over each cooking appliance

- Automatic fuel shut-offs for gas and electric

Another distinction of a UL 300 system is the type of discharge nozzle. UL 300-compliant systems feature nozzles that are:

- Narrow, ¾ inch to 1 inch in diameter

- Typically covered with blow-off metal or plastic caps

- Configured so as to have one nozzle located directly over each cooking surface

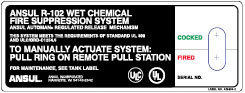

How to determine if your system is UL 300-Compliant

To find out whether your system meets the UL 300 standard:

- Check with UL (ul.com) to see whether the manufacturer’s model number is listed as UL 300-compliant, and verify that all components have been installed as specified by the manufacturer’s manual

- Locate the UL 300 label (see below) on the system’s extinguishing chemical tank or cabinet

- Contact the service provider, whose name and phone number should appear on the service record tag

A word about portable fryers

Self-contained commercial cooking devices such as portable fryers are difficult to protect with the traditional overhead suppression system. However, they too require ventilation, UL 300 controls, cleaning and regular maintenance. Portable fryers typically feature:

- A recirculation hood system designed to capture exhaust gases, filter the air and deliver it back to the appliance’s cooking chamber

- A filtration system that drains used grease

- A pump that returns the filtered hot grease to the fry pot

Class K portable fire extinguishers can supplement your kitchen safety

While the first line of defense against kitchen fires is to activate the fire extinguishing system, UL 300 designates the Class K portable fire extinguisher as a secondary backup for fires in appliances that use fats and oils. “NFPA 10: Standard for Portable Fire Extinguishers” requires that Class K extinguishers be placed within 30 feet of the hazard.3 Class K extinguishers are different from other multi-purpose models, so make sure your employees are trained to use the K extinguisher only on grease fires.

Ongoing measures to help keep your kitchen safe

NFPA 96 specifies that a certified technician clean and inspect all hoods and ducts at a minimum of every six months, but routine attention to important details is also essential. Safe commercial kitchens require a combination of sound prevention, maintenance and cleaning techniques year-round.

Prevention

To help minimize the risk of fire:

- Choose self-contained commercial cooking appliances that comply with NFPA 96 standards

- Install all cooking appliances that produce grease-laden vapors under the hood and duct system

- Place all cooking units on level, sturdy, noncombustible surfaces

- Keep all combustible materials at least 18 inches from cooking equipment

- Locate deep fryers at least 18 inches from any open flames, or protect them with a metal baffle that extends at least 8 inches above the fryer surface

- Hard-wire all electrical systems and components; never use extension cords or temporary wiring

- Replace heat-sensitive links every six months or sooner so excessive grease buildup won’t interfere with their performance

- Train your staff on how to activate the extinguishing system

- Train your staff on proper inspection and cleaning methods

Maintenance

While a certified technician should service, test, inspect, repair and recharge your fire suppression system twice yearly and immediately after any major hood or duct cleaning, you should perform a monthly inspection to ensure that all the following factors are present:

- A properly located extinguishing system

- A hood, duct and protected cooking appliances that have not been replaced, modified or moved

- No obvious physical damage that could prevent proper operation of the system

- Nozzle blow-off caps that are undamaged and free of grease buildup

- Unobstructed manual actuators

- Intact tamper indicators and seals

- Class K fire extinguishers that are pressurized and easily accessible

Cleaning

In addition to the twice-yearly cleaning and inspection by a qualified contractor, you should clean hoods, grease removal devices, fan ducts and other equipment to bare metal throughout the year to prevent the accumulation of grease or oily sludge on surface areas. You should also:

- Remove and clean all filters and grease traps at least weekly

- Inspect and clean fryers daily

- Keep the certificate showing the most recent date of inspection and major cleaning on display in your kitchen area

Should you retrofit or replace an outdated system?

Today, most state governments mandate that newly installed restaurant fire suppression systems be UL 300-compliant. However, state law is inconsistent in enforcing UL 300 compliance for existing systems. Because dry chemical systems neither pass UL 300 nor conform to NFPA 96 standards, retrofitting an old system is not recommended, and is even restricted in some jurisdictions.

In addition, there are four practical reasons to replace an outdated fire suppression system.4 Your new state-of-the art system can help you:

- Protect people and property

- Protect your revenue stream

- Protect your ability to be insured at a reasonable cost

- Protect your food service business against a major financial loss due to litigation

If you feel it may be time to install a new system:

- Meet with a licensed professional to review NFPA 96- and UL 300-compliant systems

- Have an experienced contractor install the system

- Ask an inspector to examine the completed installation and verify that it complies with all applicable federal, state and local standards

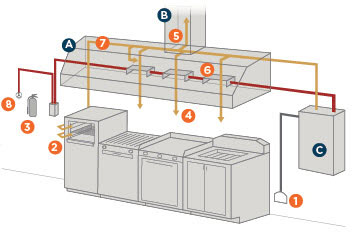

The modern commercial kitchen fire suppression system

Typical system components

Typical system components

A — Hood

B — Exhaust duct

C — Automatic extinguishing system and control box

1 — Automatic fuel shut-off

2 — Broiler nozzle

3 — Class K fire extinguisher

4 — Cooking surface nozzles

5 — Duct nozzles

6 — Fusible links

7 — Plenum nozzles

8 — Remote manual pull station

Requirements for a UL 300 system

- Nozzles located in the hood and duct

- Nozzles located over each cooking appliance

- Manual pull station

- Automatic fuel shut-offs for gas and electric

- UL 300-compliant wet chemical extinguishing system

- Wet chemical extinguishing system serviced every six months by an authorized, licensed service company

- Hood and duct maintenance and cleaning performed every six months by an authorized, licensed service company

- Baffle filter cleaning recommended weekly

We have over 100 resources to help restaurant owners ensure that their business is safe for customers and employees. Visit the Nationwide Loss Control Services Restaurants page for more information.

For your risk management and safety needs, contact Nationwide Loss Control Services: 1-866-808-2101 or LCS@nationwide.com.

[2] “ NFPA 70: National Electrical Code®,” National Fire Protection Association, http://bit.ly/1S5fmOs (2014, downloaded 3/24/16).

[3] “NFPA 10: Standard for Portable Fire Extinguishers,” National Fire Protection Association, http://bit.ly/1UVLSGo (2013, downloaded 3/24/16).

[4] “4 Reasons to Upgrade to a UL 300-Standard Fire Suppression System,” FSR Magazine, http://bit.ly/1YpzVGT (2013, downloaded 3/24/16).